Precision Micromanufacturing: Redefining Industrial Scalability

The miniaturization of industrial processes is ushering in a new era of manufacturing precision. Precision micromanufacturing, a cutting-edge approach to producing microscale components and devices, is revolutionizing industries from electronics to medical technology. This innovative methodology combines advanced materials science, state-of-the-art equipment, and intricate process control to fabricate products with unprecedented accuracy and efficiency.

The Evolution of Miniaturization in Manufacturing

The journey towards precision micromanufacturing began with the semiconductor industry’s push for ever-smaller electronic components. As Moore’s Law predicted the doubling of transistor density every two years, manufacturers were compelled to develop increasingly precise fabrication techniques. This drive for miniaturization soon spread beyond electronics, influencing sectors such as aerospace, automotive, and biomedical engineering.

Early attempts at micromanufacturing were limited by the available tools and materials. Traditional machining methods struggled to achieve the required precision at microscales. However, advancements in technologies like photolithography, laser micromachining, and electron beam lithography paved the way for more sophisticated micromanufacturing processes.

Enabling Technologies in Precision Micromanufacturing

At the heart of precision micromanufacturing are several key technologies that enable the creation of microscale components with exacting tolerances. Micromachining techniques, such as micro-electrical discharge machining (micro-EDM) and ultrasonic micromachining, allow for the removal of material at the micron level with unprecedented accuracy.

Additive manufacturing, often referred to as 3D printing, has also evolved to accommodate micromanufacturing needs. Two-photon polymerization, for instance, uses laser light to solidify photosensitive resins, creating structures with sub-micron resolution. This technology has found applications in creating micro-optics and complex biomedical devices.

Lithography-based techniques, borrowed from the semiconductor industry, have been adapted for broader micromanufacturing applications. Processes like deep reactive ion etching (DRIE) enable the creation of high-aspect-ratio microstructures in silicon and other materials, crucial for microelectromechanical systems (MEMS) and sensors.

Applications Across Industries

The impact of precision micromanufacturing is far-reaching, touching numerous industries and enabling innovative products that were previously impossible to produce. In the medical field, micromanufactured components are revolutionizing drug delivery systems, diagnostic devices, and implantable technologies. Micro-needles, for example, allow for painless and precise drug administration, while miniaturized sensors enable continuous health monitoring.

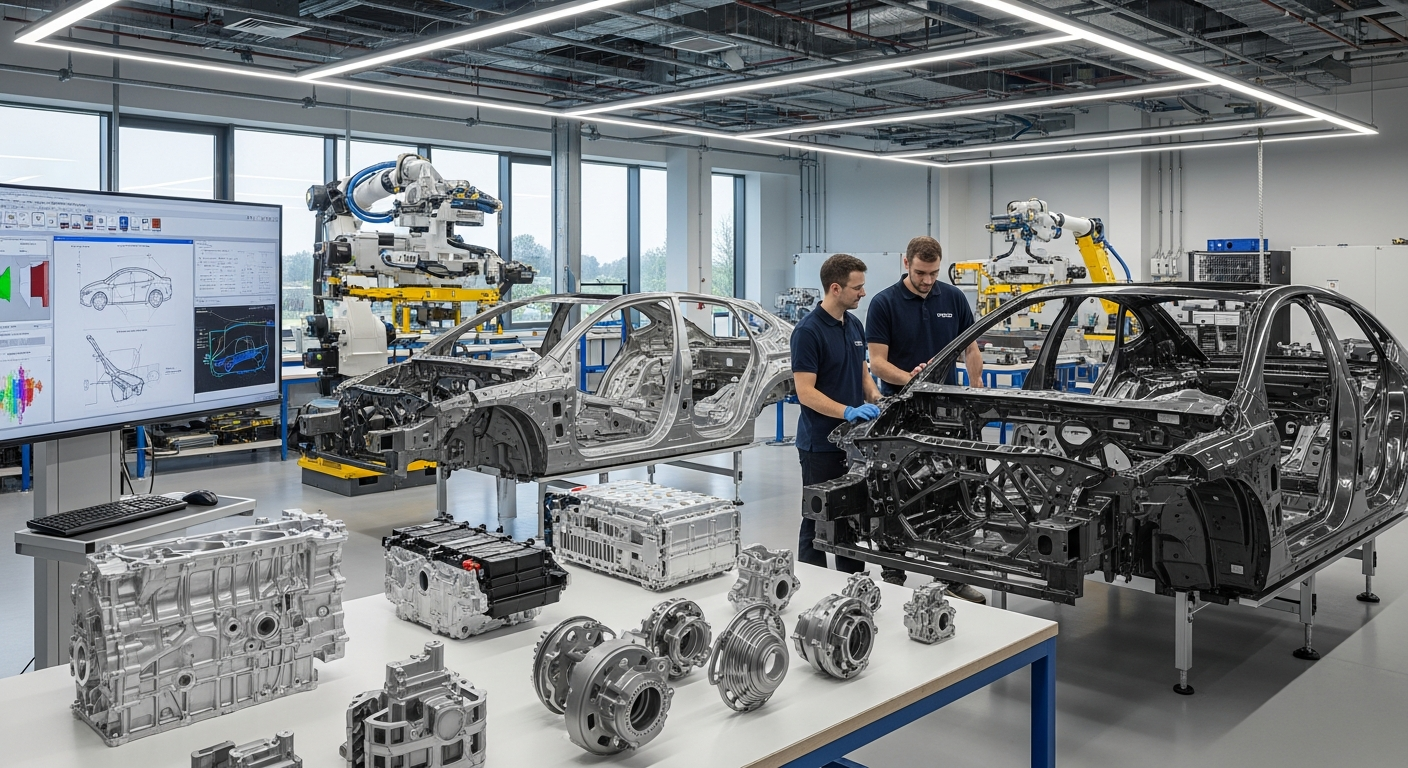

In the automotive and aerospace sectors, micromanufactured components are enhancing fuel efficiency and safety. Microscale fuel injectors improve combustion efficiency, while tiny accelerometers and gyroscopes form the basis of advanced navigation and stability control systems.

The electronics industry continues to push the boundaries of miniaturization, with micromanufacturing enabling the production of ever-smaller and more powerful devices. From smartphones to wearable tech, the ability to create intricate microstructures is driving innovation in consumer electronics.

Challenges and Future Directions

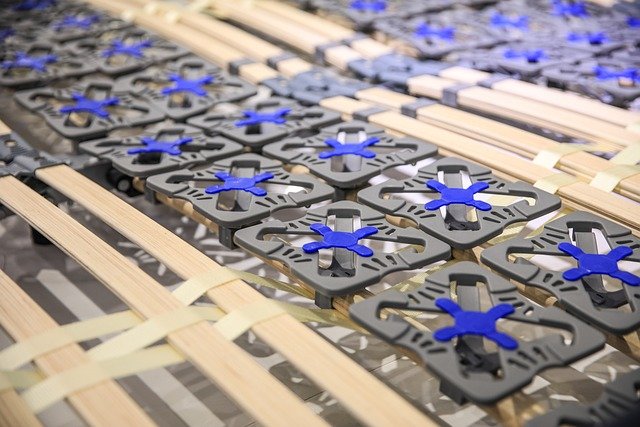

Despite its tremendous potential, precision micromanufacturing faces several challenges. Quality control at the microscale is inherently difficult, requiring sophisticated metrology tools and techniques. The handling and assembly of microscale components present unique challenges, often necessitating specialized robotic systems and clean room environments.

Material behavior at the microscale can differ significantly from macroscale properties, requiring new approaches to material science and engineering. Researchers are exploring novel materials and composites specifically designed for micromanufacturing applications.

Looking ahead, the future of precision micromanufacturing is bright. Advances in nanotechnology are blurring the lines between micro and nano-scale manufacturing, opening up new possibilities for creating structures at the atomic level. The integration of artificial intelligence and machine learning into micromanufacturing processes promises to enhance precision and efficiency further.

Economic Implications and Market Growth

The precision micromanufacturing market is experiencing rapid growth, driven by increasing demand across various industries. Market analysts project substantial expansion in the coming years, with some estimates suggesting a compound annual growth rate (CAGR) of over 10% through 2026.

This growth is attracting significant investment in research and development, as well as in manufacturing infrastructure. Companies are racing to develop proprietary micromanufacturing technologies, recognizing their potential to provide a competitive edge in the global market.

The economic implications extend beyond direct market growth. Precision micromanufacturing is enabling the development of more efficient and capable products across industries, potentially driving broader economic growth and productivity gains.

Micromanufacturing Insights for Business Leaders

-

Assess your product portfolio for potential miniaturization opportunities

-

Invest in workforce training to develop micromanufacturing expertise

-

Consider partnerships with specialized micromanufacturing firms to access cutting-edge capabilities

-

Stay informed about emerging micromanufacturing technologies and their potential impacts on your industry

-

Evaluate the long-term cost-benefits of adopting micromanufacturing processes

-

Explore government grants and incentives for adopting advanced manufacturing technologies

As precision micromanufacturing continues to evolve, it promises to reshape industrial practices and product capabilities across sectors. By enabling the creation of smaller, more efficient, and more sophisticated components, this technology is driving innovation and opening up new possibilities for businesses worldwide. Companies that recognize and harness the potential of precision micromanufacturing will be well-positioned to lead in their respective industries, creating products that were once thought impossible and pushing the boundaries of what technology can achieve.